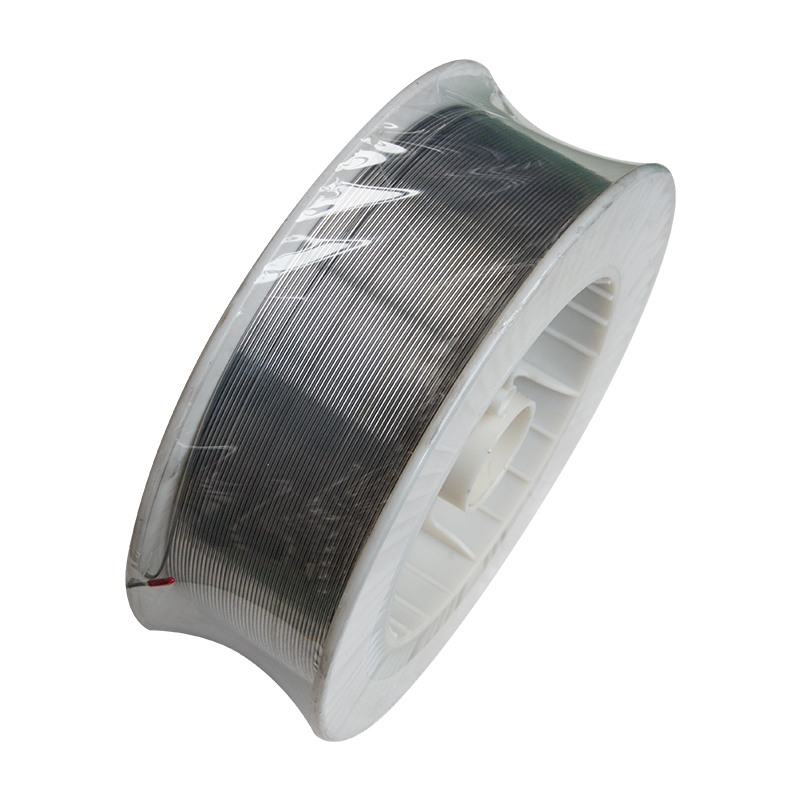

Vacon 12 Fe-Ni-Co Kaca Sealing Alloy Wire Kovar Alloy Wire

Vacon 12Kawat Paduan Penyegel Kaca Fe-Ni-CoKovarKawat Paduan

(Jeneng Umum:Kovar, Nilo K, KV-1, Dilver Po, Vacon 12)

Spesifikasi:Lembaran/Pelat, Batang/Batang/Kawat/Kumparan, Kapiler/Pipa/Tabung

Kisaran Ukuran:

—*Lembar_Kekandelan 0.1mm ~ 40.0mm, jembar: ≤300mm, Kondisi: digulung adhem (panas), padhang, padhang dipanasake

—*BunderDiameter Kawat 0.1mm~Diameter 5.0mm, Kondisi: ditarik adhem, padhang, padhang dipanasake

—*Kawat RataDiameter 0.5mm~Diameter 5.0mm, dawane: ≤1000mm, Kondisi: digulung rata, dipanasake padhang

—*BarDiameter 5.0mm~Diameter 8.0mm, dawane: ≤2000mm, Kondisi: ditarik adhem, padhang, padhang dipanasake

Diameter 8.0mm~Diameter 32.0mm, dawane: ≤2500mm, Kondisi: digulung panas, padhang, padhang dipanasake

Diameter 32.0mm~Diameter 180.0mm, dawane: ≤1300mm, Kondisi: ditempa panas, dikupas, dibalik, diolah panas

—*Kapiler_OD 8.0mm~1.0mm, ID 0.1mm~8.0mm, dawane: ≤2500mm, Kondisi: ditarik adhem, padhang, padhang dipanasake

—*Pipa_OD 120mm~8.0mm, ID 8.0mm~129mm, dawa: ≤4000mm, Kondisi: ditarik adhem, padhang, padhang dipanasake

Aplikasi:

Utamane digunakake ing komponen vakum listrik lan kontrol emisi, tabung kejut, tabung penyalaan, magnetron kaca, transistor, colokan segel, relay, kabel sirkuit terpadu, sasis, braket lan segel omah liyane.

Komposisi normal%

| Ni | 28.5~29.5 | Fe | Bal. | Co | 16.8~17.8 | Si | ≤0.3 |

| Mo | ≤0.2 | Cu | ≤0.2 | Cr | ≤0.2 | Mn | ≤0.5 |

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

Kekuwatan Tarik, MPa

| Kode kahanan | Kondisi | Kawat | Strip |

| R | Alus | ≤585 | ≤570 |

| 1/4I | 1/4 Keras | 585~725 | 520~630 |

| 1/2I | 1/2 Keras | 655~795 | 590~700 |

| 3/4I | 3/4 Keras | 725~860 | 600~770 |

| I | Atos | ≥850 | ≥700 |

Sifat Fisik Khas

| Kapadhetan (g/cm3) | 8.2 |

| Resistivitas listrik ing 20ºC (Ωmm2/m) | 0.48 |

| Faktor suhu resistivitas(20ºC~100ºC)X10-5/ºC | 3.7~3.9 |

| Titik Curie Tc/ºC | 430 |

| Modulus Elastis, E/Gpa | 138 |

Koefisien ekspansi

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20~60 | 7.8 | 20~500 | 6.2 |

| 20~100 | 6.4 | 20~550 | 7.1 |

| 20~200 | 5.9 | 20~600 | 7.8 |

| 20~300 | 5.3 | 20~700 | 9.2 |

| 20~400 | 5.1 | 20~800 | 10.2 |

| 20~450 | 5.3 | 20~900 | 11.4 |

Konduktivitas termal

| θ/ºC | 100 | 200 | 300 | 400 | 500 |

| λ/ W/(m*ºC) | 20.6 | 21.5 | 22.7 | 23.7 | 25.4 |

| Proses pangolahan panas | |

| Anil kanggo ngurangi stres | Dipanasi nganti 470~540ºC lan tahan 1~2 jam. Adhemke |

| annealing | Ing vakum dipanasake nganti 750 ~ 900ºC |

| Wektu ditahan | 14 menit~1 jam. |

| Tingkat pendinginan | Ora luwih saka 10 ºC/menit didinginkan nganti 200 ºC |

Kategori produk

-

Telpon

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Ndhuwur