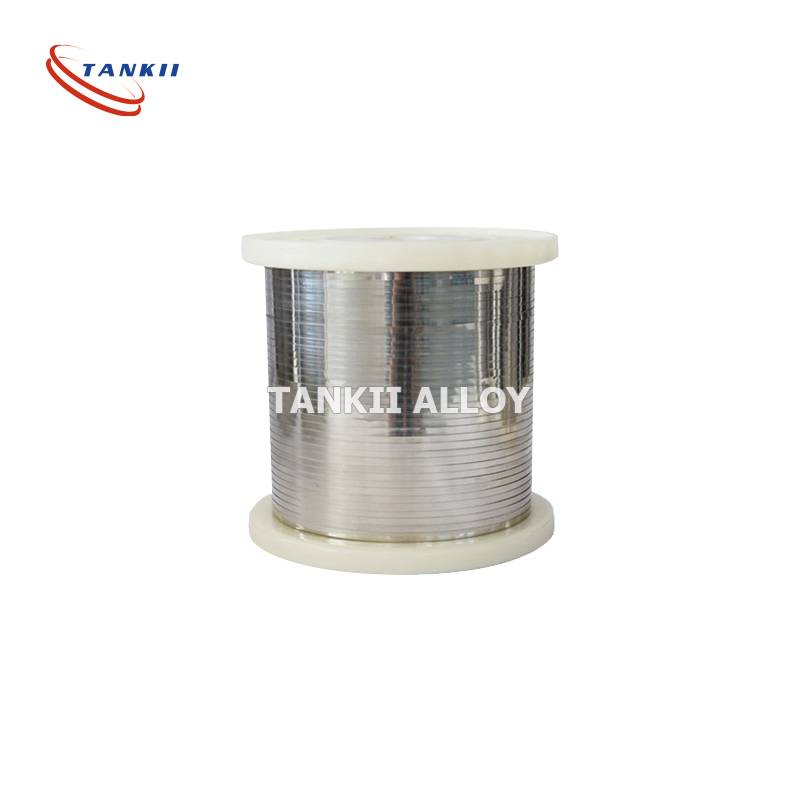

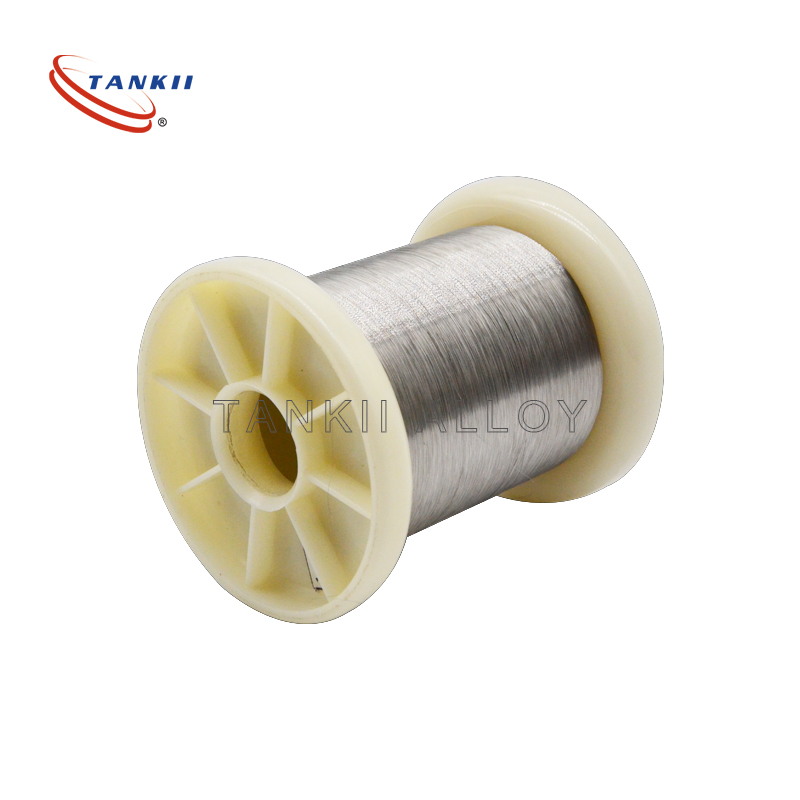

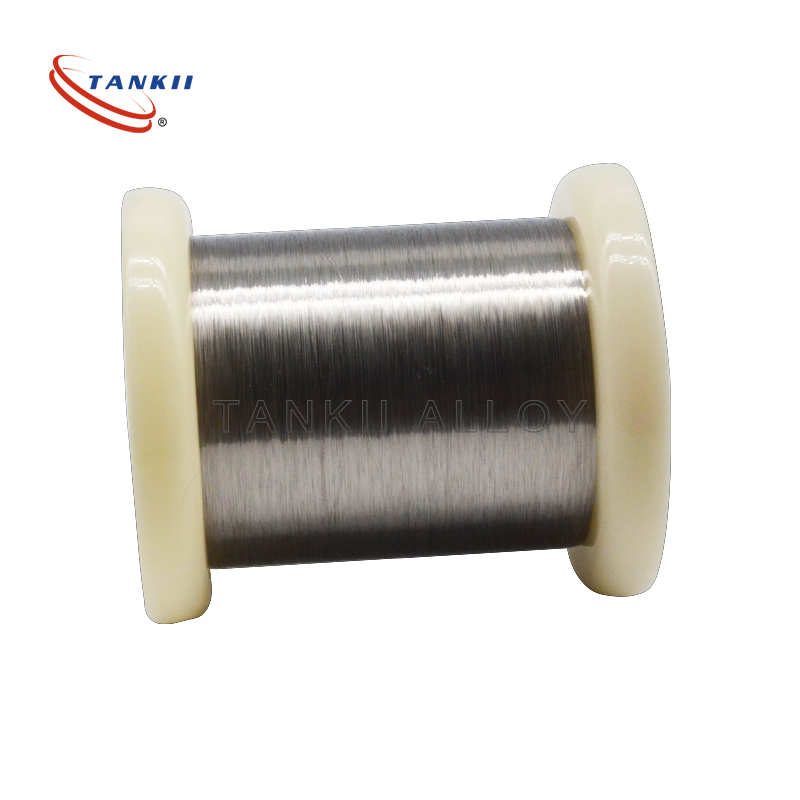

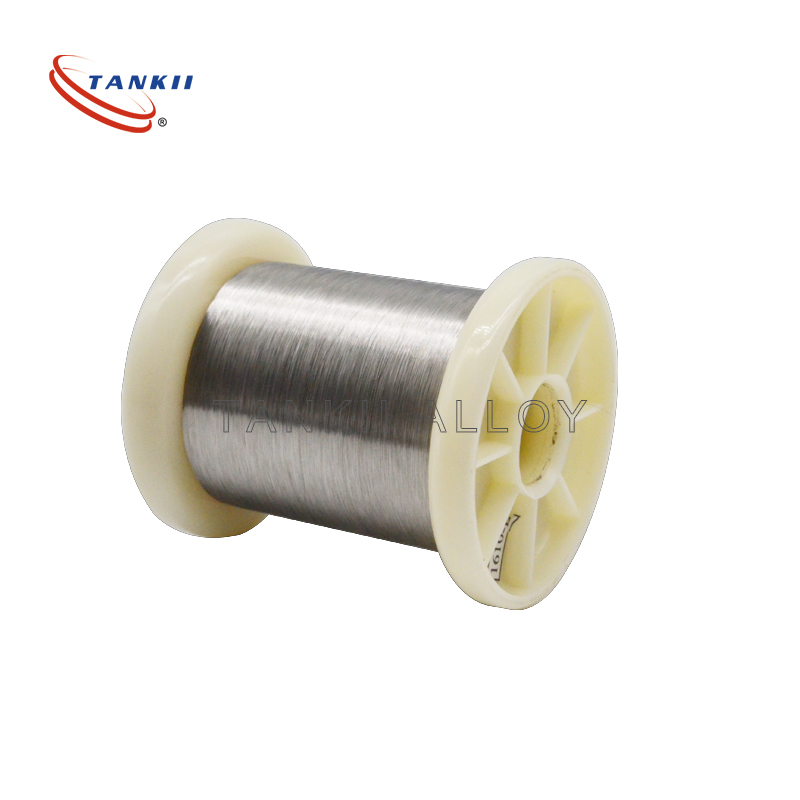

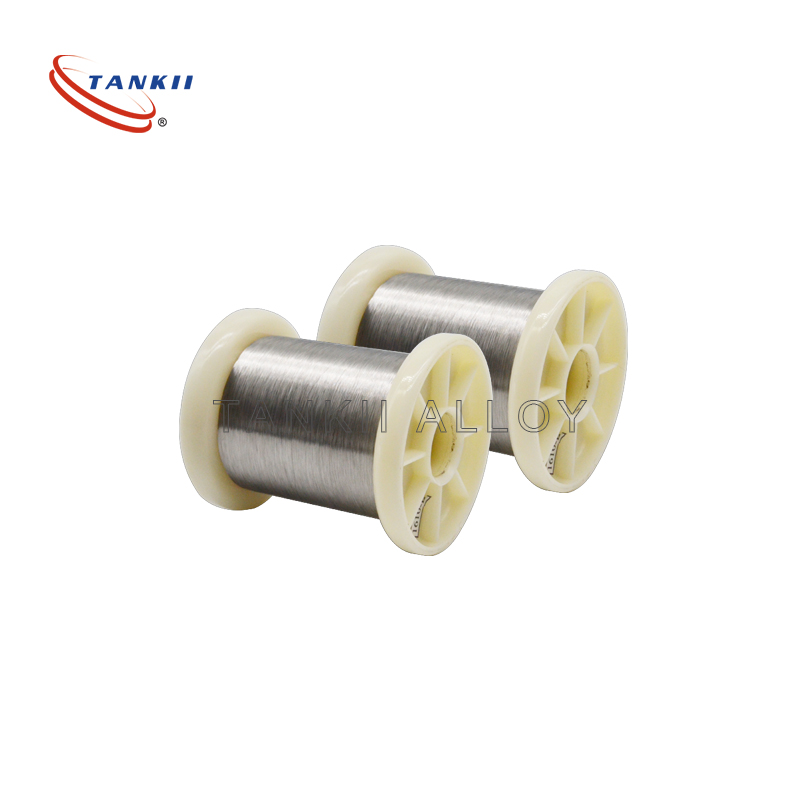

Kawat Nikel Murni (NI200 NI201) UNS NO2201 0,025mm

MurniKawat Nikel(NI200 NI201) UNS NO2201 0.025mm

| Kelas Nikel | Ni+Co | Cu | Si | Mn | C | Cr | S | Fe | Mg |

| ≥ | ≤ | ||||||||

| Ni201 | Bal. | .25 | .3 | .35 | .02 | .2 | .01 | .3 | - |

| Ni200 | Bal. | .25 | .3 | .35 | .15 | .2 | .01 | .3 | - |

![]()

![]()

![]()

![]()

Kawat nikel

Karakteristik lan Aplikasi Kawat Nikel

1) Konduktivitas listrik sing dhuwur

2) Resistivitas listrik sing endhek

3) Kondisi permukaan lan pinggiran celah sing apik banget

4) Peningkatan kemampuan soldering minangka asil saka oksida permukaan sing sithik

5) Kemampuan mbentuk sing apik banget kanthi karakteristik tarikan sing jero kanthi keausan die sing luwih sithik

6) Resistensi marang pertumbuhan gandum

7) Batere sing bisa diisi ulang (Nikel Logam Hidrida, Lithium Ion), Stamping Logam, 8) Rangka Timbal, Gasket lan Segel, Aplikasi Pencahayaan, Aplikasi Superkonduktor

Toleransi Dimensi Strip Nikel

| Kekandelan (mm) | Toleransi Ketebalan | Burr dhuwur | Toleransi Jembar (mm) | |||||

| 2≤w <10 | 10≤w <50 | 50≤w <100 | 100≤w <150 | 150≤w <200 | 200≤w ≤500 | |||

| 0,02≤t<0,05 | +0.002, -0.003 | ≤0.005 | ±0,05 | ±0.10 | ±0.15 | ±0.20 | ±0.30 | ±0.50 |

| 0,05≤t<0,1 | ±0.005 | ≤0.01 | ||||||

| 0.1≤t<0.2 | ±0.008 | ≤0.015 | ||||||

| 0.2≤t<0.3 | ±0.012 | ≤0.02 | ||||||

| 0.3≤t<0.4 | ±0.015 | ≤0.03 | ±0.10 | ±0.15 | ±0.25 | ±0.50 | ±0.80 | ±1.00 |

| 0.4≤t<0.6 | ±0.025 | ≤0,05 | ||||||

| 0.6≤t<0.8 | ±0.030 | ≤0.06 | ±0.30 | ±0.40 | ±0.50 | ±0.50 | ±0.80 | ±1.00 |

| 0.8≤t<1.0 | ±0.040 | |||||||

| 1.0≤t<1.2 | ±0.050 | ≤0.08 | ±0.50 | ±0.50 | ±0.80 | ±1.00 | ±1.00 | ±1.50 |

| 1.2≤t<1.4 | ±0.060 | |||||||

| 1.4≤t<1.7 | ±0.070 | ≤0.10 | ||||||

| 1.7≤t<2.0 | ±0.080 | |||||||

![]()

![]()

![]()

![]()

Aplikasi Kawat Nikel

Piranti listrik lan mesin kimia, dhasar filter sing kuwat, kisi-kisi katup, komponen njero katup vakum, komponen ing njero tabung elektron, timbal

kawat, kawat pendukung, produksi baterai, lapisan vakum, elektroda percikan api, dan penukar panas

Shanghai Tankii Alloy Material Co., Ltd. spesialis ing produksi Ni-Cr Alloy, Cu-Ni Alloy, Fechral, kawat termokopel,nikel murnilan bahan paduan presisi liyane awujud kawat, strip, batang, bar lan pelat.

Dimensi lan Toleransi (mm)

| Diameter | 0.025-0.03 | >0.03-0.10 | >0.10-0.40 | >0.40-0.80 | >0.80-1.20 | >1.20-2.00 |

| Toleransi | ±0.0025 | ±0.005 | ±0.006 | ±0.013 | ±0.02 | ±0,03 |

![]()

![]()

![]()

![]()

Kategori produk

-

Telpon

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Ndhuwur