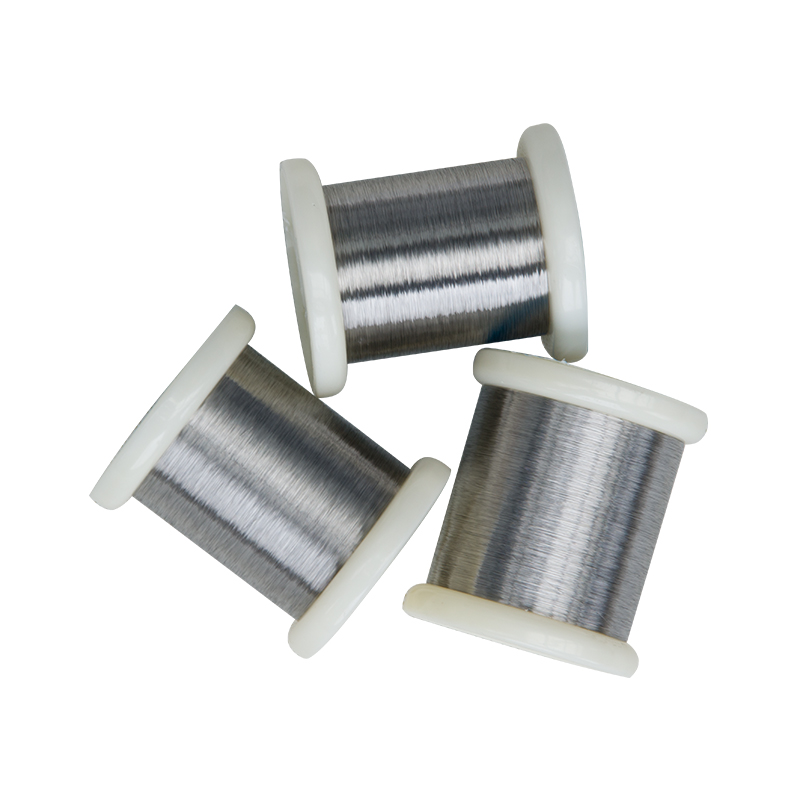

Nikel Murni 200/Uns No2200 Kawat 0.25mm

Nikel Murni 200/Uns No2200 Kawat 0.25mm

Kelas:Ni200,Ni201,N4,N6

Daktilitas dhuwur

Ketahanan korosi sing apik banget

kekuatan mekanik sing apik

Katrangan Paduan

Nikel 200/201 minangka kelas sing paling akeh digunakake, umume ditemtokake kanggo tutup transistor, anoda kanggo tabung elektronik, kabel komponen elektronik / Kabel Timbal kanggo lampu lan kanggo Wire-Mesh. Uga digunakake ing bentuk strip kanggo macem-macem aplikasi kalebu baterei Ni-Cd.

Kahanan Pasokan

Nikel 200, 201 lan 205 disedhiyakake ing kahanan ing ngisor iki:

Adhem, Temperamen Khusus.

Ditarik adhem, diudhek. Dilurusake lan dipotong dawane.

Cathetan:

NUS N02201 (ASTM B 162) padha karo N4 (GB/T 2054).

NUS N02200 (ASTM B 162) padha karo N6 (GB/T 2054).

Formulir

Gulungan - Strip, Foil, Pita

Kawat - Profil, Bunder, Rata, Kothak

batang, batang, tempa, piring, lembaran

Komposisi kimia

| Kelas | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

| N4 | 99.9 | 0.015 | 0.03 | 0.002 | 0.01 | 0.01 | 0.001 | 0.001 | 0.04 |

| N6 | 99.6 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

| Ni201 | 99.0 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

| Ni200 | 99.0 | 0.20 | 0.30 | 0.30 | 0.15 | / | 0.01 | / | 0.40 |

![]()

![]()

![]()

![]()

Kapabilitas Foil Nikel

| Kelas | Strip Nikel Murni 99,6% / 99,9% |

| Kekandelan | 0,002 nganti 2,50 mm |

| Toleransi | +/- 5% (toleransi khusus kasedhiya) |

| Jembar | Jembaré nganti 350mm |

| Ukuran koil | Nganti 80 kg tanpa las |

| Rentang Temperatur | Dipanasi nganti atos banget |

![]()

![]()

![]()

![]()

Presisi Produk Foil Nikel

| Kekandelan | Kekandelan tunjangan | Burr dhuwur | Cakupan jembar lan toleransi | |||||

| 2≤w<10 | 10≤w<50 | 50≤w<100 | 100≤w<150 | 150≤w<200 | 200≤w | |||

| 0,02≤t<0,05 | ±0.003 | ≤0.005 | ± 0.05 | ±0.10 | ±0.15 | ±0.20 | ±0.30 | ±0.50 |

| 0,05≤t<0,1 | ±0.005 | ≤0.01 | ||||||

| 0.1≤t<0.2 | ±0.008 | ≤0.015 | ||||||

| 0.2≤t<0.3 | ±0.012 | ≤0.02 | ||||||

| 0.3≤t<0.4 | ±0.015 | ≤0.03 | ± 0.10 | ±015 | ±0.25 | ±0.50 | ±0.80 | ±1.00 |

| 0.4≤t<0.6 | ±0.025 | ≤0,05 | ||||||

| 0.6≤t<0.8 | ±0.030 | ≤0.06 | ± 0.30 | ±0.40 | ±0.50 | ±0.50 | ±0.80 | ±1.00 |

| 0.8≤t<1.0 | ±0.040 | |||||||

| 1.0≤t<1.2 | ±0.050 | ≤0.08 | ± 0.50 | ±0.50 | ±0.80 | ±1.00 | ±1.00 | ±1.50 |

| 1.2≤t<1.4 | ±0.060 | |||||||

| 1.4≤t<1.7 | ±0.070 | ≤0.10 | ||||||

| 1.7≤t<2.0 | ±0.080 | |||||||

![]()

![]()

![]()

![]()

Kategori produk

-

Telpon

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Ndhuwur