Sugeng rawuh ing situs web kita!

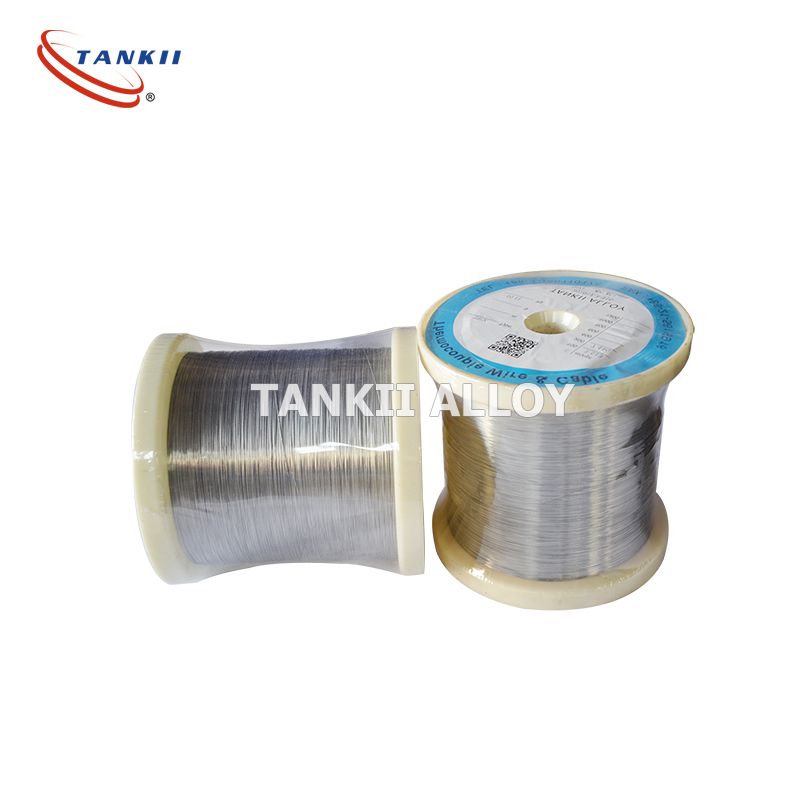

Kawat paduan nikel krom Ni70Cr30

Kawat paduan nikel kromNi70Cr30

Strip Kumparan Elektrotermal Paduan Nikrom Cr30Ni70, Tahan Sable Kanggo Elemen Pemanas,

NiCr70/30

Paduan nikel kromium kanthi resistivitas elektrotermal tahan wesi, awak permukaan apik banget. Ing suhu dhuwur lan intensitas dhuwur,

lan kinerja lan pangolahan sing apik bisa uga ngelas kanthi sifat sing akeh digunakake ing komponen metalurgi, listrik, mekanik lan listrik

industri manufaktur kanggo nggawe bahan tahan panas.

Jinis NiCr: Cr20Ni80, Cr15Ni60, Cr20Ni35, Cr20Ni30, Cr25Ni20 lsp. Seri sabuk datar listrik, kabel geni listrik.

3. Ukuran produk:

Kekandelan: 0,02—-4,0mm

Jembar: 2.5—-250mm

Standar: GB1234-95

Permukaan sing padhang lan alus

Ni70Cr30

Kandungan Kimia, %

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Liyane |

| Maks. | |||||||||

| 0.08 | 0.02 | 0.015 | 0.60 | 0.75~1.60 | 28.0~31.0 | Bal. | Maks. 0.50 | Maks. 1.0 | - |

![]()

![]()

![]()

![]()

Sifat Mekanik

| Suhu Layanan Terus-menerus Maks.: Resistivitas (20ºC)/Ω·m::Kapadhetan: Konduktivitas Termal: Koefisien Ekspansi Termal: Titik Leleh: Pemanjangan: Struktur Mikrografik: Sifat Magnetik: | 1250ºC 1.18 +/-0.05 (Diameter: <0.5mm) 1,20+/-0,05 (Diameter: ≥0,50 mm) 8,1 g/cm3 45.2 KJ/m·h·ºC 17×10-6/ºC (20ºC~1000ºC) 1380ºC Minimal 20% Austenit nonmagnetik |

![]()

![]()

![]()

![]()

| Tipe | Cr20Ni80 | Cr15Ni60 | Cr30Ni70 | Cr20Ni35 | Cr20Ni30 | |

| Komposisi kimia utama | Ni | Ngaso | 55.0~61.0 | Ngaso | 34.0~37.0 | 30.0~34.0 |

| Cr | 20.0~23.0 | 15.0~18.0 | 28.0~31.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1 | Ngaso | ≤1 | Ngaso | Ngaso | |

| Suhu Maksimum (ºC) | 1200 | 1150 | 1250 | 1100 | 1100 | |

| Koefisien koreksi suhu resistensi. (CT) | 1.09±0.05 | 1.11±0.05 | 1.18±0.05 | 1,04±0,05 | 1,06±0,05 | |

| Titik leleh (ºC) | 1400 | 1390 | 1380 | 1390 | 1390 | |

| Resistivitas ρ20ºC (10-6Ω.m) | 800ºC | 1.008 | 1.078 | 1.028 | 1.188 | 1.173 |

| 1000ºC | 1.014 | 1.095 | 1.033 | 1.219 | 1.201 | |

| 1200ºC | 1.025 | 1.043 | ||||

| Nilai urip sing cepet | Suhu (ºC) | 1175 | 1100 | 1200 | 1050 | 1050 |

| jam (jam) | ≥110 | ≥100 | ≥110 | ≥100 | ≥100 | |

| Gravitasi spesifik (g/cm3) | 8.40 | 8.2 | 8.1 | 7.90 | 7.90 | |

| Pemanjangan (%) | ≥25 | ≥25 | ≥20 | ≥20 | ≥20 | |

| Termal (kj/mhºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Panas spesifik (20ºC)j/g.ºC | 0.440 | 0.494 | 0.461 | 0.500 | 0.500 | |

| Ngembangake kekuwatan (20 ~ 1000ºC)α * 10-6ºC | 18.0 | 17.0 | 17.1 | 19.0 | 19.0 | |

| Kekuwatan tarik (kg/mm2) | >85 | >85 | >85 | >85 | >85 | |

| Mlengkung bola-bali (F/R) | >12 | >12 | >12 | >12 | >12 | |

| Mikrostruktur | Austenitik | Austenitik | Austenitik | Austenitik | Austenitik | |

![]()

![]()

![]()

![]()

Tulis pesenmu ing kene lan kirim menyang kita

Kategori produk

-

Telpon

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Ndhuwur