Sugeng rawuh ing situs web kita!

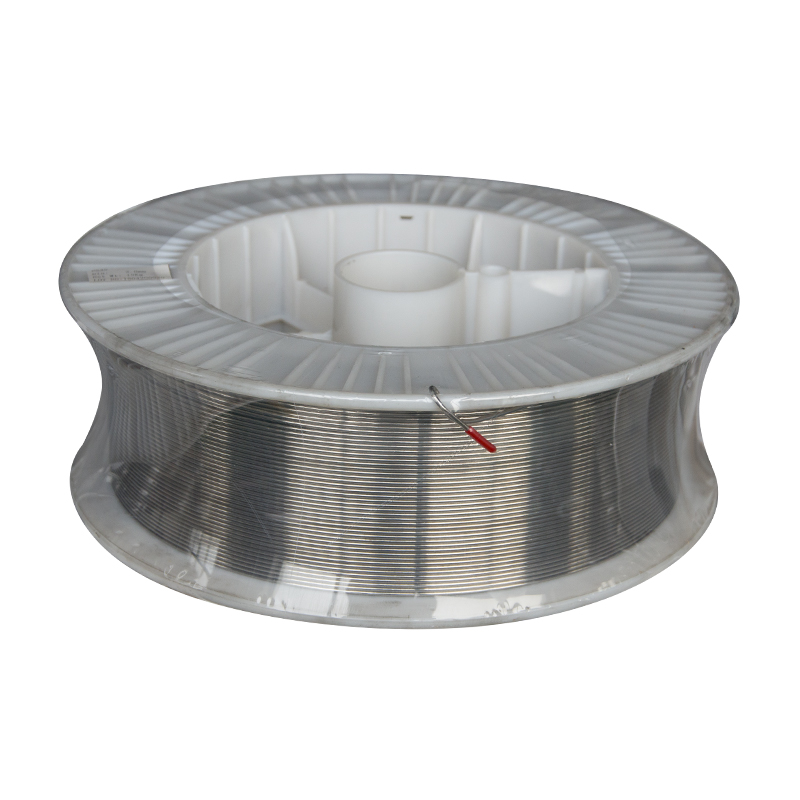

Paduan Nikel Hastelloy C276 Hc-276 Ernicrmo-4 Kawat Las MIG Batang Las TIG

Paduan nikelHastelloy C276HC-276ERNiCrMo-4MIG Welding wire TIG welding Rod

AWS A5.14:ERNiCrMo-4yaiku batang kawat padat berbasis nikel kanggo GTAW. Cocok kanggo ngelas paduan INCONEL C-276 lan paduan nikel-kromium molibdenum liyane, baja pelapis, ngelas baja karbon menyang paduan dasar nikel lan baja tahan karat menyang paduan nikel. Logam las iki tahan korosi sing dhuwur lan nuduhake resistensi sing apik banget marang korosi pitting lan crevice uga kekuatan lan ketangguhan sing dhuwur. Sifat sing apik banget nganti -196°C.

| Barang | ErNiCrMo-3 | ErNiCrMo-4 | ErNiCrMo-13 | ErNiCrFe-7 | ErNiCr-3 | ErNiCrCu-7 | ErCuNi | ErNi-1 |

| C | 0.1 | 0.02 | 0.01 | 0.04 | 0.1 | 0.15 | 0.03 | 0.15 |

| Mn | 0.05 | 1 | 0.5 | 1 | 2.5-3.5 | 4 | 0.5-1.0 | 1 |

| Fe | 5 | 4-7 | 1.5 | 7-11 | 3 | 2.5 | 0.65 | 1 |

| P | 0.02 | 0.04 | 0.015 | 0.02 | 0.03 | 0.02 | 0.01 | 0.03 |

| S | 0.015 | 0.03 | 0.005 | 0.015 | 0.015 | 0.015 | 0.01 | 0.015 |

| Si | 0.05 | 0.08 | 0.1 | 0.5 | 0.5 | 1.25 | 0.15 | 0.75 |

| Cu | 0.5 | 0.5 | Ora Ana | 0.3 | 0.5 | ngaso | ngaso | 0.25 |

| Ni | ≥58 | ngaso | ngaso | ngaso | ≥67 | 62-69 | 30-32 | ≥93 |

| Co | Ora Ana | 2.5 | 0.3 | Ora Ana | Ora Ana | Ora Ana | Ora Ana | Ora Ana |

| Al | 0.4 | Ora Ana | 0.1-0.4 | 1.1 | Ora Ana | 1.25 | 0.15 | 1.5 |

| Ti | 0.4 | Ora Ana | Ora Ana | 1 | 0.75 | 1.5-3 | 0.5 | 2-3.5 |

| Cr | 20-23 | 14.5-16.5 | 22-24 | 28.5-31 | 18-22 | Ora Ana | Ora Ana | Ora Ana |

| Nb+Ta | 3.5-4.15 | Ora Ana | 1.8-2.5 | 0.01 | 2-3 | Ora Ana | Ora Ana | Ora Ana |

| Mo | 8-10 | 15-17 | 15-16 | 0.5 | Ora Ana | Ora Ana | Ora Ana | Ora Ana |

| V | Ora Ana | 0.35 | Ora Ana | Ora Ana | Ora Ana | Ora Ana | Ora Ana | Ora Ana |

| W | Ora Ana | 3-4.5 | Ora Ana | Ora Ana | Ora Ana | Ora Ana | Ora Ana | Ora Ana |

| Ngaso | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

| Tipe | Standar | Komposisi kimia Manin % | Aplikasi khas |

| Kawat las nikel | A5.14 ERNi-1 | Ni ≥ 93 Ti3 Al1 Cr– Mo– | ERNi-1 digunakake kanggo pengelasan GMAW, GTAW lan ASAW saka Nikel 200 lan 201, nggabungake paduan kasebut karo baja tahan karat lan karbon, lan logam dasar nikel lan tembaga-nikel liyane. Uga digunakake kanggo nutupi baja. |

| Kawat las NiCulding | A5.14 ERNiCu-7 | Ni 65 Cr– Mo– Ti2 Liyane: Cu | ERNiCu-7 kuwi kawat dasar paduan tembaga-nikel kanggo pengelasan GMAW lan GTAW saka paduan Monel 400 lan 404. Uga digunakake kanggo nutupi baja. sawise pisanan ngetrapake Lapisan nikel 610. |

| Kawat las CuNi | A5.7 ERCuNi | Ni 30 Cr– Mo– Liyane: Cu | ERCuNi digunakake kanggo pengelasan busur gas logam lan gas tungsten. Uga bisa digunakake kanggo pengelasan oxy-fuel tembaga 70/30, 80/20, lan 90/10. paduan nikel. Lapisan penghalang paduan nikel 610 dianjurake sadurunge nutupi baja nganggo proses las GMAW. |

| NiCr kawat las | A5.14 ERNiCrFe-3 | Ni≥ 67 Cr 20 Mo— Mn3 Nb2.5 Fe2 | Elektroda tipe ENiCrFe-3 digunakake kanggo ngelas paduan nikel-kromium-besi karo awake dhewe lan kanggo ngelas sing beda antarane paduan lan baja nikel-kromium-wesi utawa baja tahan karat. |

| A5.14 ERNiCrFe-7 | Ni: Sisa Cr 30 Fe 9 | Tipe ERNiCrFe-7 digunakake kanggo pengelasan gas-tungsten-arc lan gas-logam-arc saka INCONEL 690. | |

| Kawat las NiCrMo | A5.14 ERNiCrMo-3 | Ni≥ 58 Cr 21 Mo 9 Nb3.5 Fe ≤1.0 | ERNiCrMo-3 digunakake utamane kanggo busur gas tungsten lan logam gas lan logam dasar sing cocog karo komposisi. Iki uga digunakake kanggo ngelas. Inconel 601 lan Incoloy 800. Iki bisa digunakake kanggo ngelas kombinasi logam sing beda-beda kayata baja, baja tahan karat, Inconel lan Paduan incoloy. |

| A5.14 ERNiCrMo-4 | Ni Rest Cr 16 Mo 16 W3.7 | ERNiCrMo-4 digunakake kanggo ngelas bahan dasar nikel-kromium-molibdenum kanggo awake dhewe, baja lan paduan dasar nikel liyane lan kanggo baja pelapis. | |

| A5.14 ERNiCrMo-10 | Ni Sisa Cr 21 Mo 14 W3.2 Fe 2.5 | ERNiCrMo-10 digunakake kanggo ngelas bahan dasar nikel-kromium-molibdenum, baja lan paduan dasar nikel liyane, lan kanggo baja cladding. Bisa digunakake kanggo ngelas baja tahan karat duplex, super duplex. | |

| A5.14 ERNiCrMo-14 | Ni Rest Cr 21 Mo 16 W3.7 | ERNiCrMo-14 digunakake kanggo pengelasan gas-tungsten-arc lan gas-logam-arc saka baja tahan karat dupleks, super-dupleks lan super-austenitik, uga paduan nikel kayata UNS N06059 lan N06022, paduan INCONEL C-276, lan paduan INCONEL 22, 625, lan 686. |

Tulis pesenmu ing kene lan kirim menyang kita

Kategori produk

-

Telpon

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Ndhuwur