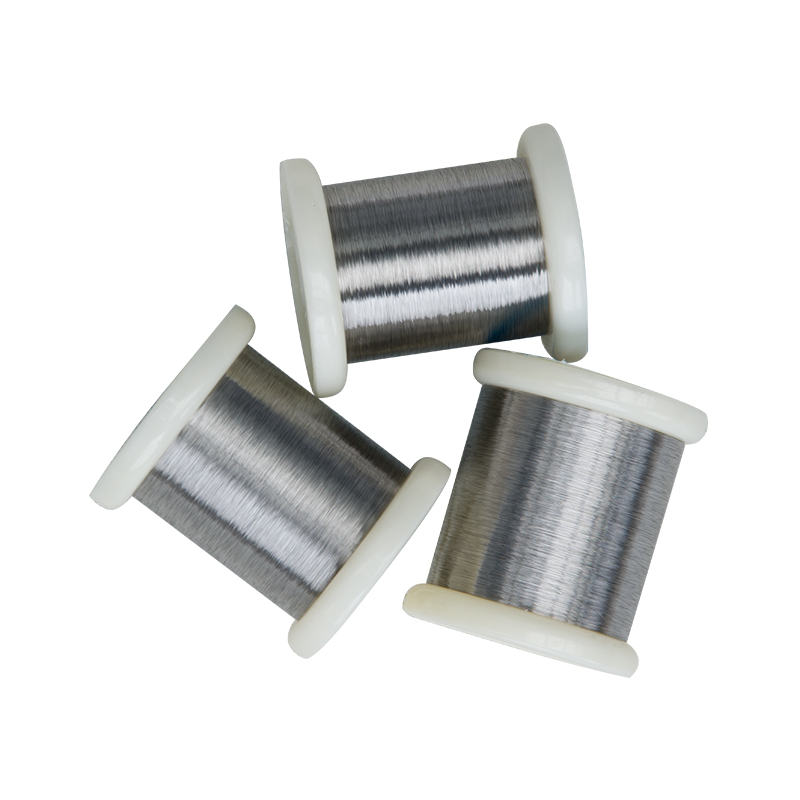

Paduan Nikel Hastelloy C276 Ernicrmo-4 Las MIG TIG Las Inconel C-276 Kawat C22, B3, B2

Hastelloy iku paduan tahan korosi berbasis nikel, sing utamane dipérang dadi rong kategori: paduan nikel-kromium lan paduan nikel-kromium-molibdenum. Hastelloy nduwèni tahan korosi lan stabilitas termal sing apik, lan umumé digunakaké ing penerbangan, bidang kimia, lan liya-liyané.

ERNiCrMo-4digunakake kanggo pengelasan gas-tungsten-arc lan gas-logam-arc saka paduan Inconel C-276 lan paduan nikel-kromium-molibdenum liyane. Amarga kandungan molibdenum sing dhuwur, paduan iki nawakake resistensi sing apik banget kanggo retak korosi stres lan korosi pitting lan celah.

Jeneng Umum: Oxford Alloy® C-276 FM C-276 Techalloy 276

Standar: AWS A5.14,ERNiCrMo-4/ ASME II, SFA-5.14, UNS N10276 Werkstoff Nr. 2.4886 ISO SNi6276 Eropa NiCrMo16Fe6W4

Ukuran: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

| Kelas | C276 | C22 | C4 | N | |||

|

Bahan kimia Komposisi (%) | C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

| Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 | |

| Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 | |

| P | ≤0,04 | ≤0.02 | ≤0,04 | ≤0,04 | – | ≤0.015 | |

| S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | – | ≤0.02 | |

| Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 | |

| Ni | ngaso | ngaso | ngaso | ngaso | ≥65 | ngaso | |

| Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 | |

| Ti+Cu | – | – | ≤0.7 | – | ≤0.4 | ≤0.35 | |

| Al+Ti | – | – | – | – | ≤0.5 | ≤0.5 | |

| Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 | |

| Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 | |

| B | – | – | – | – | – | ≤0.01 | |

| W | 3-4.5 | 2.5-3.5 | – | – | ≤3 | ≤0.5 | |

| V | ≤0.35 | ≤0.35 | – | 0.2-0.4 | – | ≤0.5 | |

Kategori produk

-

Telpon

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Ndhuwur