Sugeng rawuh ing situs web kita!

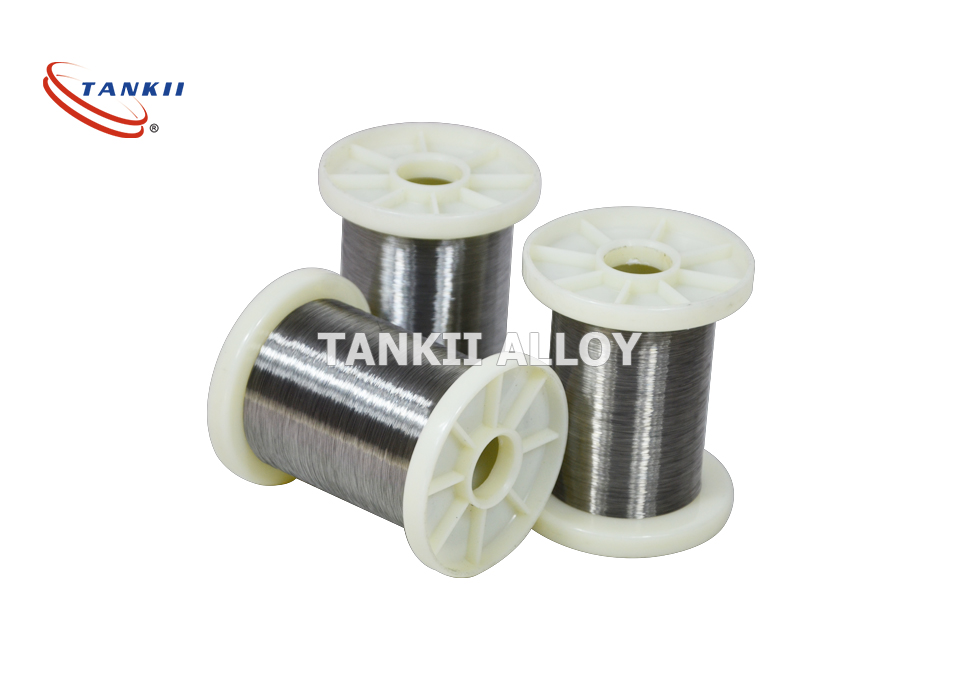

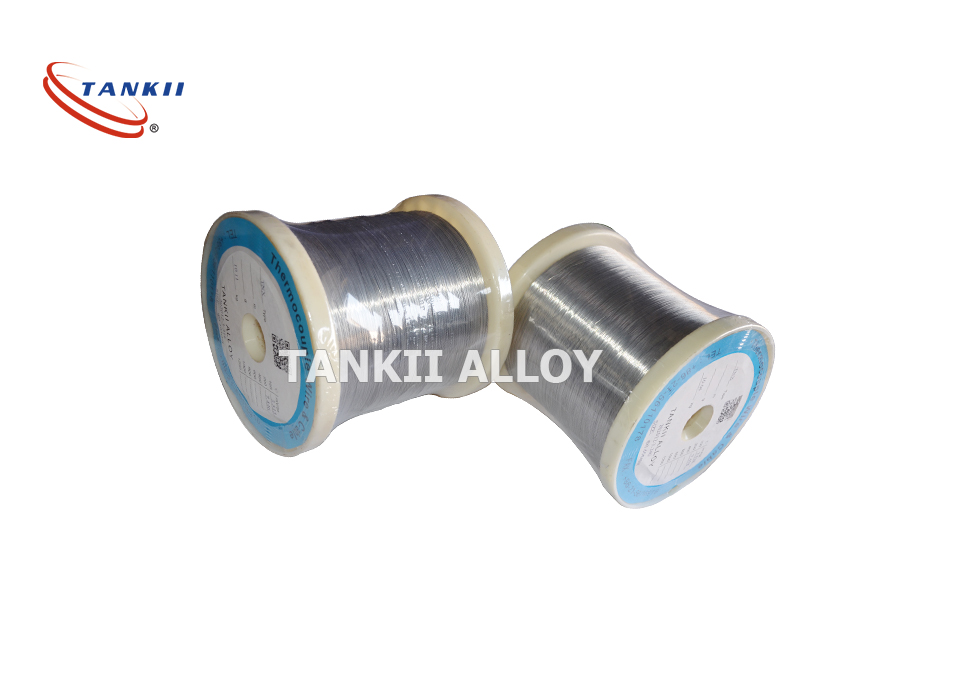

GY FeCrAl 0Cr25Al5 kabel resistance kanggo pemanas tubular

GY FeCrAl OCr25Al5 kabel resistance kanggopemanas tubular

| jeneng produk | Rentang ukuran |

| Kawat gambar kadhemen | Dhiameter 0.03-7.5mm |

| Batang kawat sing digulung panas | Dhiameter 8.0-12mm |

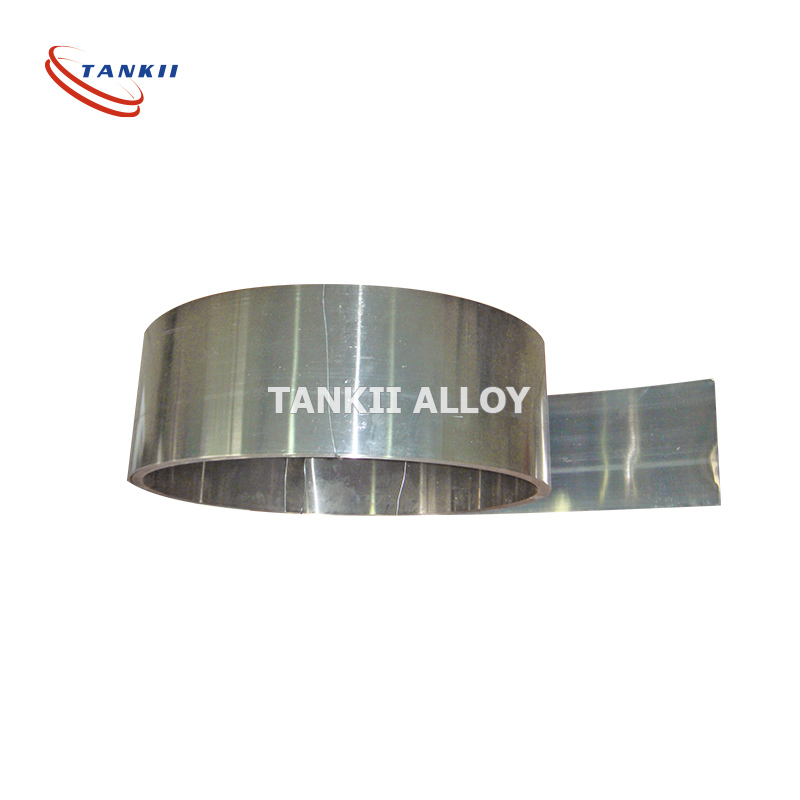

| pita | Ketebalan 0,05-0,35 mm |

| Jembaré 0.5.0-3.5mm | |

| Strip gulungan kadhemen | Ketebalan 0,5-2,5 mm |

| Jembaré 5.0-40mm | |

| panas mbalek Strip | Ketebalan 4-6 mm |

| Jembaré 15-40mm |

Babagan Resistance Heating Wire:

We are Produsèn profesional paling gedhe saka resistance panas alloy ing China, spesialisasine ing Ferro-Chrome (Fe-Cr-AL) kawat, Nikel-Chrome (Nichrome) kawat, tembaga Nikel (Constantan) kabel, Kawat baja tahan karat lan produk related ing wesi ngarang kanggo syarat customer tartamtu

Detail ukuran

paramèter dhasar:

| paramèter dhasar | Kanthall APMTM | Kanthall | ||

| A-1 | AF | D | ||

| Suhu kerja terus-terusan paling dhuwur | 1425 | 1400 | 1300 | 1300 |

| Komposisi kimia nominal,% Cr | 22 | 22 | 22 | 22 |

| AI | 5.8 | 5.8 | 5.3 | 4.8 |

| Fe | bahan | bahan | bahan | bahan |

| Ni | - | - | - | - |

| Resistivitas ing 20ºC, Ωmm-2mm-1 | 1.45 | 1.45 | 1.39 | 1.35 |

| Kapadhetan, g/cm3 | 7.1 | 7.1 | 7.15 | 7.25 |

| Koefisien ekspansi termalK-1 20-750ºC | 14×10-6 | 14×10-6 | 14×10-6 | 14×10-6 |

| 20-1000ºC | 15×10-6 | 15×10-6 | 15×10-6 | 15×10-6 |

| Konduktivitas termal 20ºC, Wm-1K-1 | 13 | 13 | 13 | 13 |

| Kapasitas panas spesifik 20ºC, KJkg-1K-1 | 0.46 | 0.46 | 0.46 | 0.46 |

| Titik leburºC | 1500 | 1500 | 1500 | 1500 |

| Mesthi, karakteristik mekanik | ||||

| Kekuwatan tarik, N mm-2 | 680 | 680 | 680 | 650 |

| Kekuwatan ngasilake, N mm-2 | 470 | 475 | 475 | 450 |

| Ketebalan, Hv | 230 | 230 | 230 | 230 |

| Pecah elongasi,% | 20 | 18 | 18 | 18 |

| Kekuwatan tensile 900ºC, N mm-2 | 40 | 34 | 37 | 34 |

| Kekuwatan creep 800ºC | 11 | 6 | 8 | 6 |

| 1000ºC | 3.4 | 1 | 1.5 | 1 |

| Magnetik | Magnetik (ing suhu 600ºC) | |||

| Emisivitas, kondisi oksidasi | 0.7 | 0.7 | 0.7 | 0.7 |

Spesifikasi:

| Tipe Alloy | Dhiameter | Resistivity | Tarik | Elongasi (%) | Mlengkung | Max. Terus-terusan | Urip Kerja |

| (mm) | (μΩm)(20°C) | Kekuwatan | kaping | Layanan | (jam) | ||

| (N/mm²) | Suhu (°C) | ||||||

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | > 20 | > 9 | 1200 | > 20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | > 20 | > 9 | 1200 | > 20000 | |

| > 3.0 | 1.14±0.05 | 850-950 | > 20 | > 9 | 1200 | > 20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | > 20 | > 9 | 1250 | > 20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | > 20 | > 9 | 1250 | > 20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | > 20 | > 9 | 1125 | > 20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | > 20 | > 9 | 1125 | > 20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | > 20 | > 9 | 1100 | > 18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | > 20 | > 9 | 1100 | > 18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | > 16 | > 6 | 950 | > 10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | > 16 | > 6 | 1000 | > 10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | > 12 | > 5 | 1300 | > 8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | > 12 | > 5 | 1250 | > 8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | > 12 | > 5 | 1300 | > 8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | > 12 | > 5 | 1100 | > 8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | > 12 | > 5 | 1350 | > 8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1,53±0,07 | 686-784 | > 12 | > 5 | 1400 | > 8000 |

Kaluwihan:

Nikelkromium alloy karo resistance dhuwur lan stabil, resistance karat, resistance oksidasi lumahing apik, sing luwih apik ing suhu dhuwur lan kekuatan seismik, ductility apik, workability apik lan weldability.

Nikelkromium alloy karo resistance dhuwur lan stabil, resistance karat, resistance oksidasi lumahing apik, sing luwih apik ing suhu dhuwur lan kekuatan seismik, ductility apik, workability apik lan weldability.

Tulis pesen ing kene lan kirimake menyang kita

Kategori produk

-

Telpon

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Ndhuwur