Sugeng rawuh ing situs web kita!

Elemen strip pemanas resistensi dhuwur FeCrAl ocr23al5 kanggo tungku

Pemanasan tahan dhuwur FeCrAl ocr23al5stripelemen kanggo tungku

| Kelas | 0Cr23Al5 |

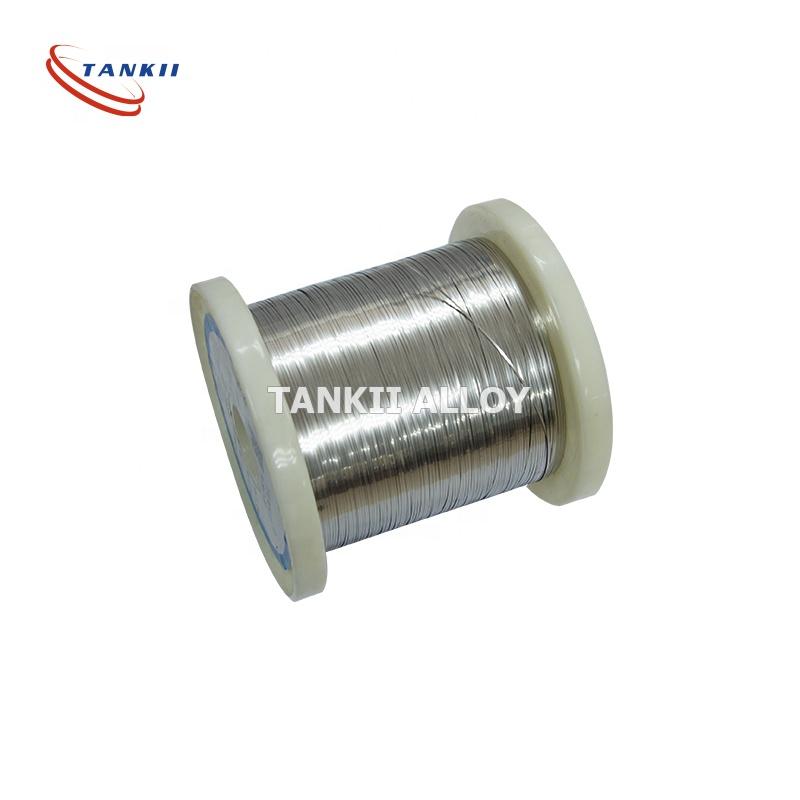

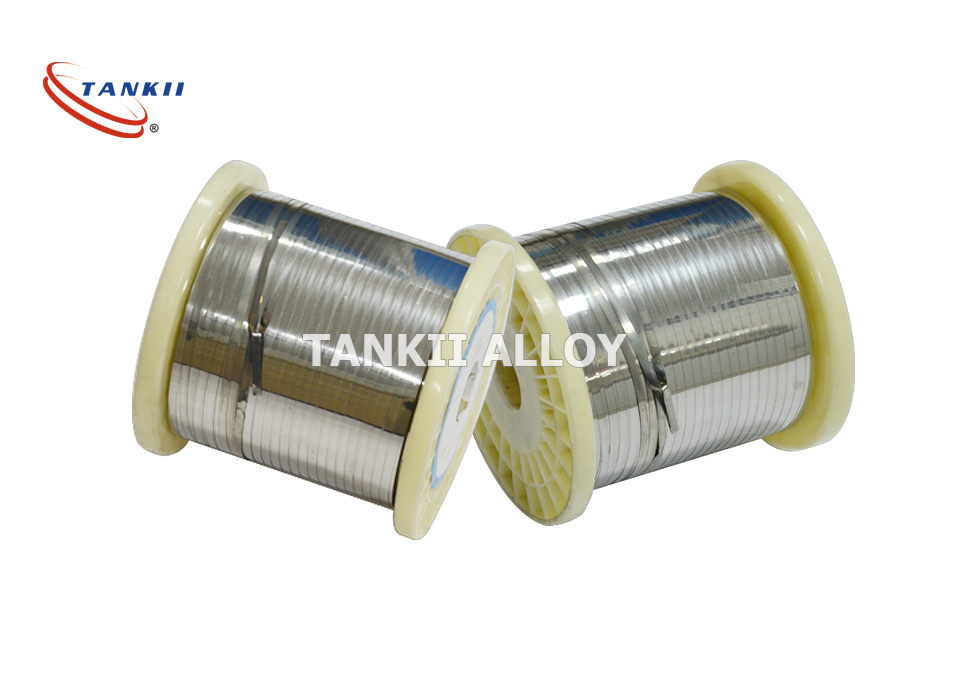

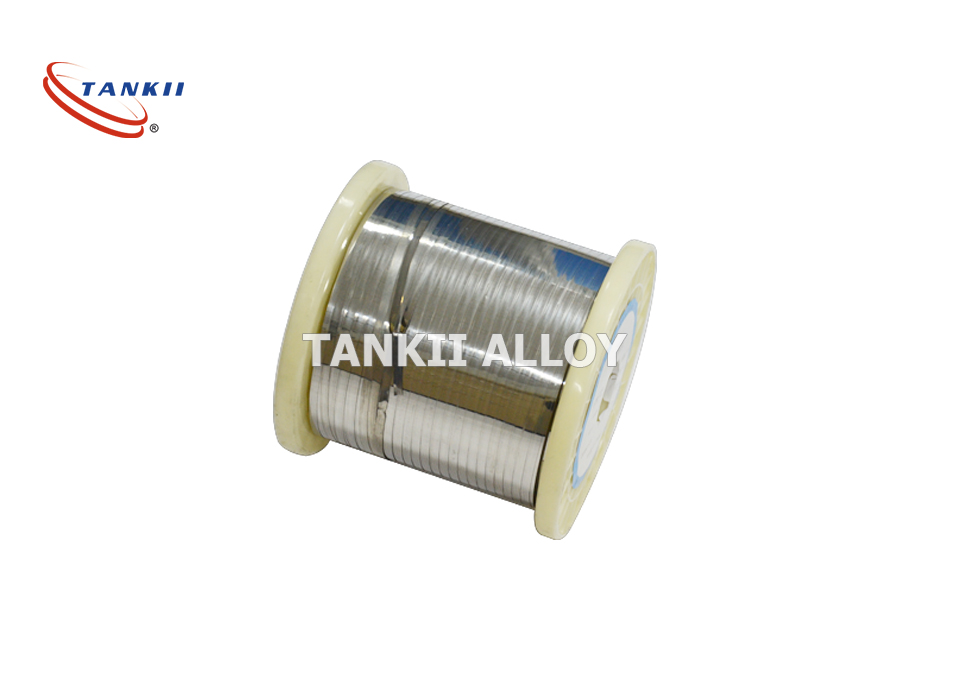

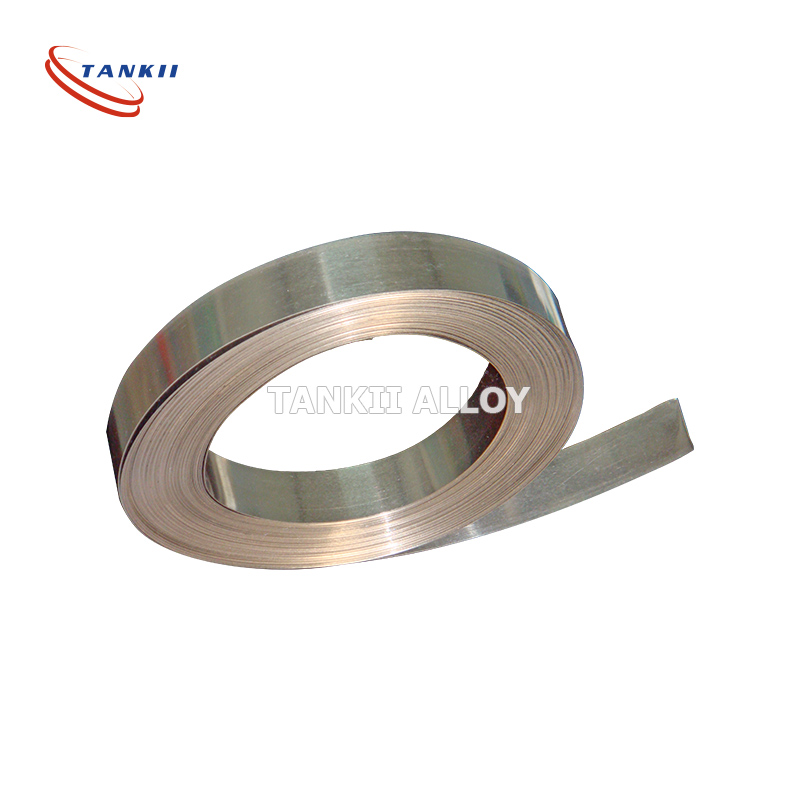

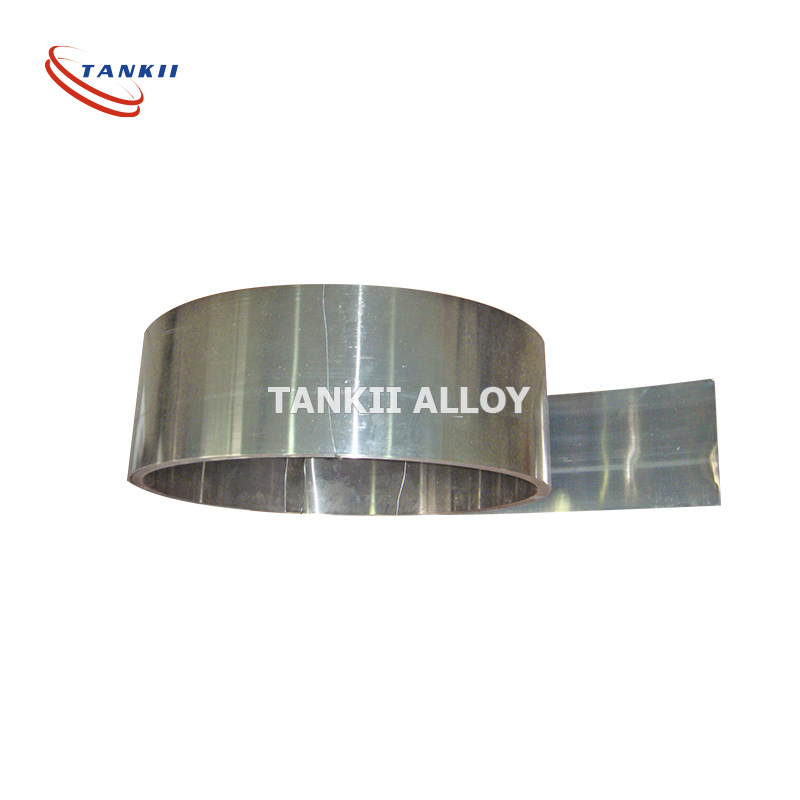

| Ukuran | kekandelan: 0,05-3mm jembaré: 4-250mm |

| Permukaan | irisan padhang |

| Bobot | 1-3kg/gulungan, miturut jumlah pelanggan |

| Resistivitas | 1.3±0.05μΩ.m |

| Kekerasan (HV) | 180-210HV |

| Pemanjangan | ≥16% |

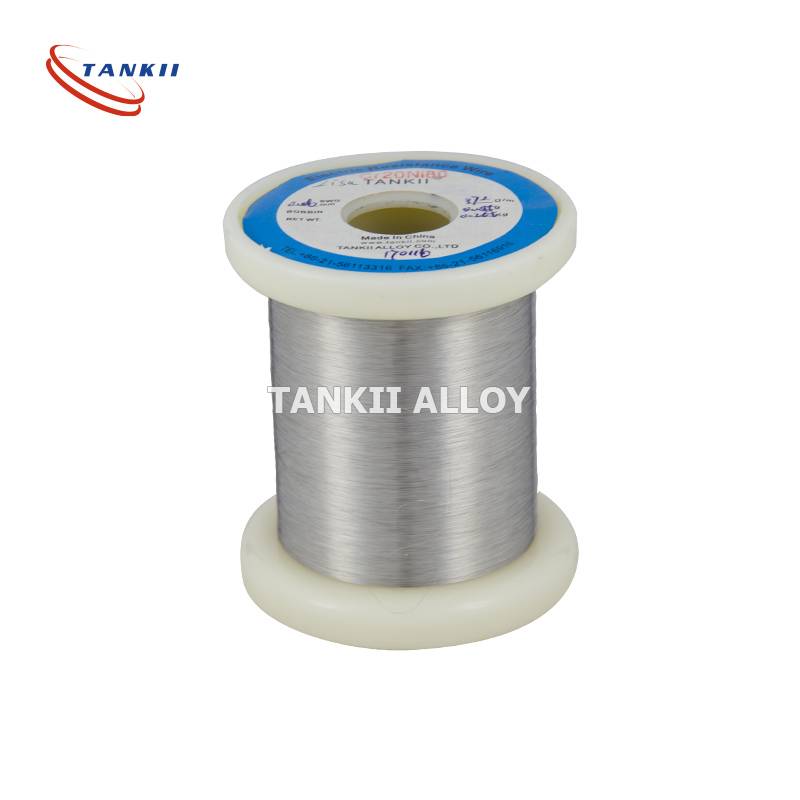

Shanghai Tankii ALloy Material Co.,Ltd. fokus ing produksi paduan nikrom, kawat termokopel, paduan fecral, paduan presisi, paduan tembaga nikel, paduan semprotan termal, lan liya-liyane ing wangun kawat, lembaran, pita, strip, batang lan pelat.

Kita wis entuk sertifikat sistem mutu ISO 9001 lan persetujuan sistem perlindungan lingkungan ISO 14001. Kita duwe set lengkap aliran produksi canggih kanggo penyulingan, reduksi adhem, nggambar lan ngolah panas, lan liya-liyane. Kita uga bangga duwe kapasitas R&D independen.

| Kelas | Suhu paling dhuwur | Resistivitas | Kekerasan | Kekuwatan tarik | Pemanjangan |

| 0Cr13Al4 | 1050℃ | 1,25±0,05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr15Al5 | 1100℃ | 1.3±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr21Al6Nb | 1300℃ | 1,42±0,05μΩ.m | 200-240HV | 750N/mm2 | ≥12 |

| Cr20Ni80 | 1200℃ | 1,09±0,05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr15Ni60 | 1150℃ | 1.12±0.05μΩ.m | 175-210HV | 750N/mm2 | ≥20 |

| Cr20Ni35 | 1100℃ | 1,04±0,05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr25Ni20(310S) | 1100℃ | 0,86±0,05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Kelas | Komposisi kimia% | ||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | |

| ≤ | |||||||||

| 0Cr15Al5 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | imbangan |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.02 | 0.5 | ≤0.6 | 21-23 | ≤0.6 | 5-7 | imbangan |

| 0Cr13Al4 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | imbangan |

| Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 20-23 | imbangan | <0.5 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 15-18 | 55-61 | <0.5 | imbangan |

| Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1.0 | 1-3 | 18-21 | 34-37 | - | imbangan |

| Cr25Ni20 | 0.08 | 0.045 | 0.03 | 2.0 | 0.4-0.6 | 24-26 | 19-22 | - | imbangan |

Tulis pesenmu ing kene lan kirim menyang kita

Kategori produk

-

Telpon

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Ndhuwur