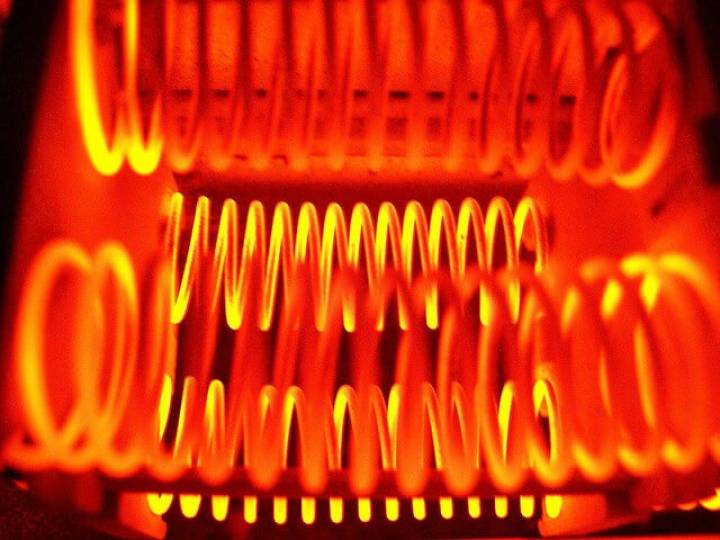

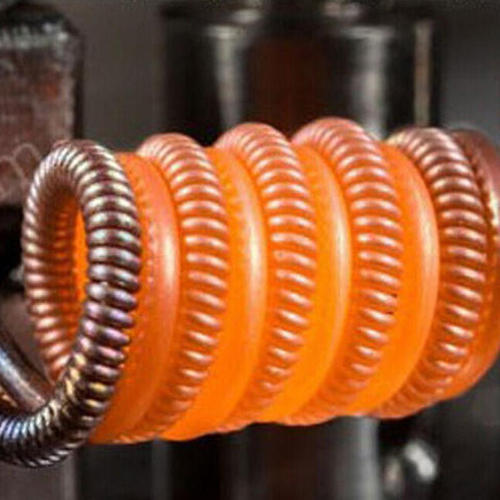

Koil pemanas kawat kompor listrik FeCrAl 0Cr25Al5

Sifat Utama saka kawat tahan panas

| Tipe Paduan | Diameter (mm) | Resistivitas (μΩm)(20°C) | Tarik Kekuwatan (N/mm²) | Pemanjangan (%) | Mlengkung Wektu | Maks. Terus-terusan Layanan Suhu (°C) | Urip Kerja (jam) |

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1,04±0,05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1,06±0,05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1,45±0,07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

| NAMA | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| KIMIA UTAMA | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| KOMPOSISI | Re | sing cocog | sing cocog | sing cocog | sing cocog | sing cocog | sing cocog | sing cocog |

| Fe | Ngaso | Ngaso | Ngaso | Ngaso | Ngaso | Ngaso | Ngaso | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| SUHU MAKSIMUM (oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| RESISTANSI 20oC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| KAPATENAN (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| PERTUKARAN PANAS | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| TINGKAT (KJ/m·h·oC) | ||||||||

| laju ekspansi (α×10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| titik leleh (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| kekuatan tarik (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| pemanjangan (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| variasi area (%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| frekuensi mlengkung (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| kekasaran (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| struktur mikrografik | Ferit | Ferit | Ferit | Ferit | Ferit | Ferit | Ferit | |

| sifat magnetik | Magnetik | Magnetik | Magnetik | Magnetik | Magnetik | Magnetik | Magnetik | |

| Diameter (mm) | Toleransi (mm) | Diameter (mm) | Toleransi (mm) |

| 0.03-0.05 | ±0.005 | >0.50-1.00 | ±0.02 |

| >0.05-0.10 | ±0.006 | >1.00-3.00 | ±0,03 |

| >0.10-0.20 | ±0.008 | >3.00-6.00 | ±0,04 |

| >0.20-0.30 | ±0.010 | >6.00-8.00 | ±0,05 |

| >0.30-0.50 | ±0.015 | >8.00-12.0 | ±0.4 |

| Kekandelan (mm) | Toleransi (mm) | Jembar (mm) | Toleransi (mm) |

| 0.05-0.10 | ±0.010 | 5.00-10.0 | ±0.2 |

| >0.10-0.20 | ±0.015 | >10.0-20.0 | ±0.2 |

| >0.20-0.50 | ±0.020 | >20.0-30.0 | ±0.2 |

| >0.50-1.00 | ±0.030 | >30.0-50.0 | ±0.3 |

| >1.00-1.80 | ±0.040 | >50.0-90.0 | ±0.3 |

| >1.80-2.50 | ±0.050 | >90.0-120.0 | ±0.5 |

| >2.50-3.50 | ±0.060 | >120.0-250.0 | ±0.6 |

Aku Kita minangka produsen kawat tahan panas kalebu

kawat FeCrAL, kawat NiCr, kawat CuNi:

II Kauntungan Utama lan Aplikasi

A. Parameter fisik:

1) Diameter kawat: 0,025 ~ 15mm

2) Nikel murni nduweni kemampuan kanggo tahan suhu sing relatif dhuwur tanpa rusak. Operasi maksimal

suhu kira-kira 600°C

3) Kawat nikel kasedhiya ing konstruksi untaian tunggal utawa multi-untaian. Iki disedhiyakake saka stok, apa iku kosong, utawa terisolasi

B. Ciri-cirine:

1) Kelurusan sing apik banget

2) Kondisi permukaan sing seragam lan ayu tanpa bintik-bintik

3) Kemampuan mbentuk koil sing apik banget

C. Aplikasi utama lan tujuan umum:

1) Kawat iki uga bisa digunakake sacara wiyar ing kahanan sing umume ditemtokake kanggo tutup transistor, anoda kanggo tabung elektronik,

kabel komponen elektronik / kabel timbal kanggo lampu lan kanggo wire-mesh. Uga digunakake ing bentuk strip kanggo macem-macem

aplikasi kalebu baterei Ni-Cd

2) Uga digunakake kanggo kabel, Kawat-ing-Kabel kanggo lampu, penyangga tabung elektronik, kabel penghubung listrik kain kawat

ing ngendi suhu ngluwihi suhu sing cocog kanggo tembaga, kawat anyaman

3) Aplikasi umum kalebu: terminasi kanggo elemen pemanas kaya ing oven, ekstruder plastik, tungku.

Pendukung filamen lan kabel timbal ing industri pencahayaan

Kategori produk

-

Telpon

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Ndhuwur