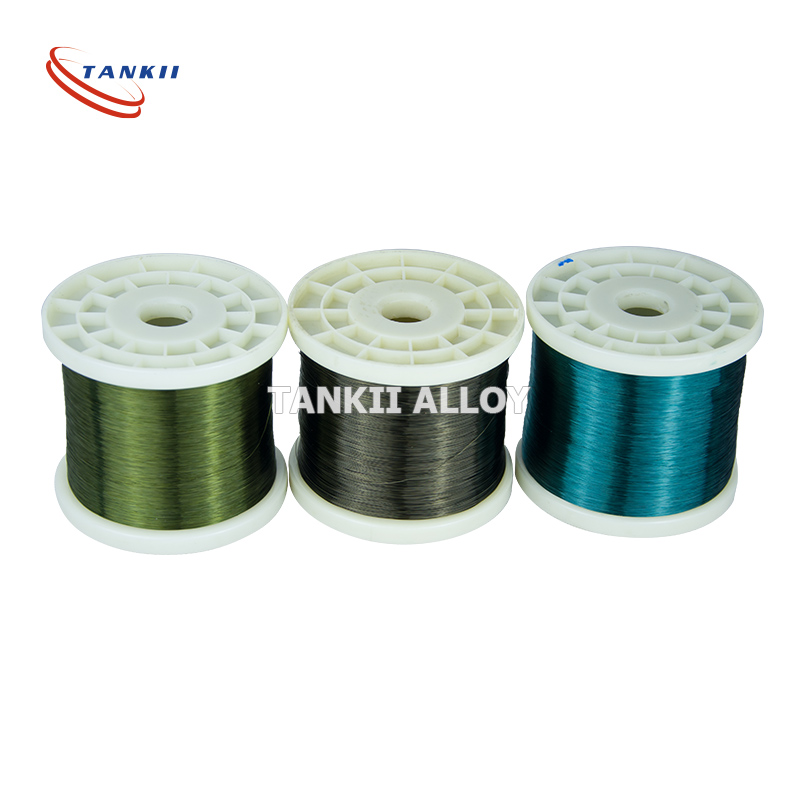

Kawat tembaga termal kelas C / 200*C ANSI TYPE MW35C utawa IEC 317-13. Kawat gulungan enamel dilapisi ganda poliester-imida lan poliamida-imida

kawat tembaga kelas termal C/ 200*C ANSI TIPE MW35C utawa IEC 317-13. Poliester-imida lanpoliamida-imidaKawat gulungan enamel dilapisi ganda

Katrangan Produk

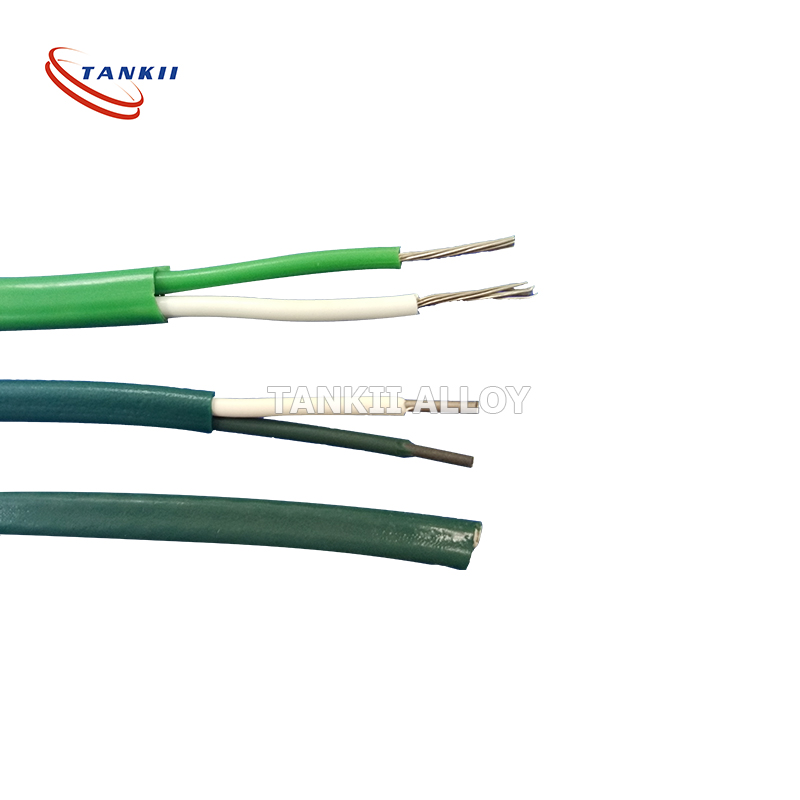

Kabel resistensi enamel iki wis digunakake sacara wiyar kanggo resistor standar, mobil, lan liya-liyane.

bagean, resistor lilitan, lan liya-liyane nggunakakeinsulasipangolahan sing paling cocog kanggo aplikasi kasebut, kanthi njupuk kauntungan saka fitur khas lapisan enamel.

Kajaba iku, kita bakal nindakake lapisan enamelinsulasisaka kawat logam mulia kayata kawat perak lan platinum miturut pesenan. Mangga gunakake fitur produksi-sajrone pesenan iki.

Jinis Kawat Nikrom

NiCr80/20,NiCr70/30,NiCr60/15,NiCr90/10,NiCr35/20,NiCr30/20

Jinis Isolasi

| Jeneng sing dilapisi insulasi | Tingkat TermalºC (wektu kerja 2000 jam) | Jeneng Kode | Kode GB | JENIS ANSI |

| Kawat enamel poliuretan | 130 | UEW | QA | MW75C |

| Kawat enamel poliester | 155 | PEW | QZ | MW5C |

| Kawat enamel poliester-imida | 180 | EIW | QZY | MW30C |

| Kawat enamel dilapisi ganda poliester-imida lan poliamida-imida | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Kawat enamel poliamida-imida | 220 | AIW | QXY | MW81C |

Jinis Kawat Paduan Bare

Paduan sing bisa digawe nganggo enamel yaiku kawat paduan tembaga-nikel, kawat Constantan, kawat Manganin. Kawat Kama, kawat Paduan NiCr, kawat Paduan FeCrAl, lan liya-liyane.

| utama properti jinis | Cuni1 | CuNI2 | CuNI6 | CuNi8 | CuNI10 | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | ||

| utama bahan kimia komposisi | Ni | 1 | 2 | 6 | 8 | 10 | 14.2 | 19 | 23 | 30 | 34 | 44 | |

| MN | / | / | / | / | / | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | ||

| CU | ngaso | ngaso | ngaso | ngaso | ngaso | ngaso | ngaso | ngaso | ngaso | ngaso | ngaso | ||

| maksimal nyambut gawe suhu | / | 200 | 220 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 400 | ||

| kapadhetan g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | ||

| resistivitas ing suhu 20°C | 0,03 ± 10% | 0,05± 10% | 0.10± 10% | 0.12± 10% | 0.15± 10% | 0.20± 5% | 0.25± 5% | 0.30± 5% | 0.35± 5% | 0.40± 5% | 0.49± 5% | ||

| suhu koefisien saka perlawanan | <100 | <120 | <60 | <57 | <50 | <38 | <25 | <16 | <10 | -0 | <-6 | ||

| tarik kekuwatan mpa | >210 | >220 | >250 | >270 | >290 | >310 | >340 | >350 | >400 | >400 | >420 | ||

| pemanjangan | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | ||

| leleh titik °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | ||

| koefisien saka konduktivitas | 145 | 130 | 92 | 75 | 59 | 48 | 38 | 33 | 27 | 25 | 23 |

Kawat pemanas paduan nicr8020

1. Babagan kawat Nichrome

Paduan nikrom kalebu nikel murni, paduan NiCr, paduan Fe-Cr-Al lan paduan nikel tembaga.

Paduan nikel krom: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, nikel murni Ni200 lan Ni201

2. Kauntungan Utama lan Aplikasi

1. Nikel-kromium, paduan nikel-kromium kanthi resistensi dhuwur lan stabil, tahan korosi, tahan oksidasi permukaan apik, luwih apik ing suhu dhuwur lan kekuatan seismik, daktilitas apik, kemampuan kerja lan kemampuan las sing apik.

2. Produk kita akeh digunakake ing industri kimia, mekanisme metalurgi, industri kaca, industri keramik, area peralatan rumah tangga lan liya-liyane.

3. Komposisi kimia:

| Merek | Komposisi kimia | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| Ora luwih saka | |||||||||

| Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | tetep | ≤0.50 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | tetep |

| Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | tetep |

| Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | tetep |

Nalika produk ana ing status "M", kudu dituruti standar GB/T1234-1995

Resistivitas:

| Merek | Cr20Ni80 | Cr20Ni60 | Cr20Ni35 | Cr20Ni30 | ||

| Diameter mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| resistivitas (20°C)uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1,04±0,05 | 1,06±0,05 |

Kategori produk

-

Telpon

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Ndhuwur